Convenience, cost, and versatility mean laminate flooring is distinct from hardwood surfaces. However, as is the case with both solid and engineered boards, you must also provide a space between the planks closest to the walls, when installing laminate floors.

This space is referred to as an expansion gap and ensures your floor surface will remain even when the boards expand due to rising humidity and temperature levels.

Experts recommend a minimum of 8 – 10 inches (or a quarter of an inch, in some cases).

However, the right size depends on the size of the surface being covered.

Here we discuss the importance of expansion gaps and possible issues involving them to ensure you are equipped with the knowledge you need to get started with your laminate flooring.

Do You Need An Expansion Gap for Laminate Flooring?

Yes, you do. To understand why this is the case, it is important to take a glimpse at the structure of a laminate floorboard and also to understand what happens if you do not provide an expansion gap during installation.

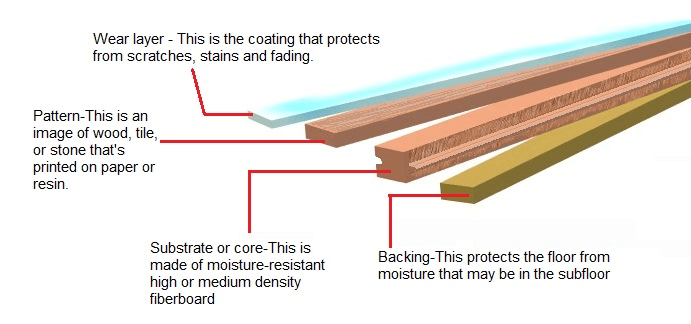

The Structure of Laminate Flooring

Laminate floor planks consist of four layers.

The first is the wear layer which is transparent and designed to protect the lower photographic layer from UV damage and wear and tear.

Next comes the photographic layer which consists of a high-resolution image of either wood, marble, or even non-conventional designs such as greenery or imagery.

Below this comes a board layer which is made from high-density fiberboard (also referred to as HDF) in laminate flooring produced according to the highest standards.

It is this layer that consists of wood that has been milled and combined with a binder and pressed into planks.

The entire structure is supported by a base layer, which provides it with stability.

The presence of the HDF layer (certain manufacturers may use MDF or medium-density fiberboard), means that a significant portion of laminate flooring consists of wood.

As a matter of fact over 90% of a board is made of this organic material which is not only porous but hygroscopic, i.e., capable of attracting moisture.

As a result, laminate planks are susceptible to the relative humidity of their surroundings.

That means that they will contract or expand owing to changes in this all-important factor, just like solid or engineered hardwood would, as well.

For this reason, a gap must be left between the row of boards closest to the wall and the wall itself during installation.

What Happens When You Don’t Install an Expansion Gap?

When humidity levels rise, particularly during warmer seasons, the wood in your laminate flooring will expand.

If there is no space between them this may result in the following issues with your planks:

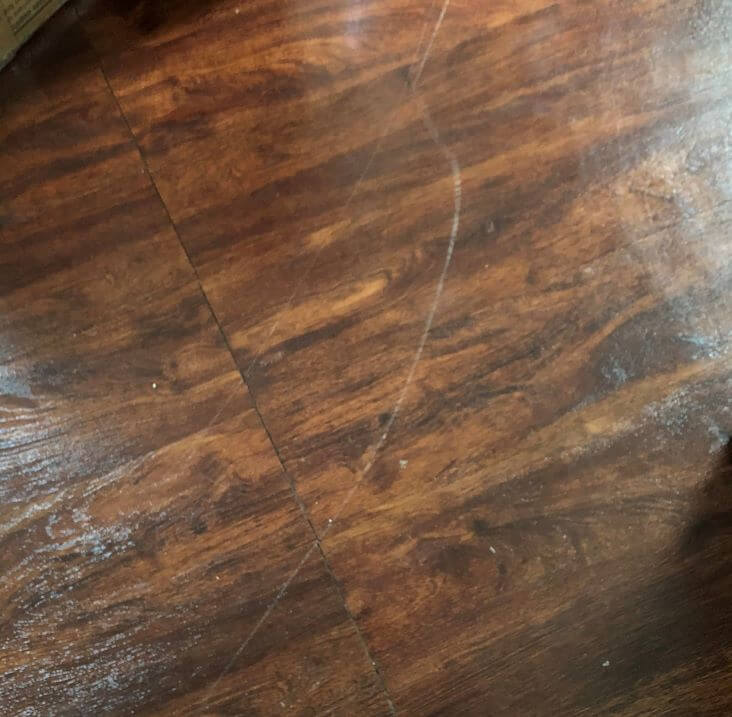

1) Peaking: This problem occurs when laminate boards push up against each other at the seams creating slopes on your flooring surface.

It can be resolved by noting the direction in which the expansion occurs, removing the molding on the facing wall, and cutting the board which happens to be pressing into the wall causing the peaking in the floorboards.

2) Buckling: Like peaking, buckling in laminate floors is caused when humidity levels rise. However, it can also be caused by the direct exposure of the laminate floorboards to moisture as a result of wet mopping, neglecting to clean spills at once, or undetected leakages.

In the absence of sufficient space to expand, i.e., the absence of an expansion gap, the floorboards will push up against each other.

For the problem to be resolved, you will need to ascertain the cause of the excess moisture and repair any leakages or clean any spills. It may be necessary to replace your moisture barrier if it is insufficient for handling moisture from the concrete subfloor.

You will also need to remove the molding and cut an expansion gap if none has been provided.

What Size Expansion Gap Is Needed for Laminate Flooring?

The size of the expansion gap required for your floor will depend on the size of your surface and most manufacturers will provide you with the measurements you need.

That said, most experts recommend a minimum of one-quarter of an inch.

Expansion gaps aren’t just needed close to the walls of a room but may also be required at the centers of rooms exceeding 8 meters in width and 12 meters in length.

They are also required when transitioning from one room to another, particularly in the event of different surfaces being involved, i.e., laminate and tile, for example.

Transition profiles that serve to cover these gaps will come in handy here: each board on either side will have to be placed 5 millimeters on either side of the bar of each profile.

Can You Have Too Big of an Expansion Gap for Laminate Flooring?

Yes, you can. There are a few issues that could cause the problem such as neglecting to use floor spacers.

This issue could also be caused by failure to acclimatize your laminate boards by placing them on the floor of the room in which they are meant to be installed for a minimum of 48 hours.

Failing to take these precautions may result in you having to fix expansion gaps which turn out to be too large as a result.

How to Hide an Expansion Gap?

Several methods can be used to resolve or even prevent large expansion gaps.

These include:

1. Adding Molding or Beading

When using either option you will need to select a product that matches your color scheme as closely as possible.

You will also need to ensure you select the appropriate size of molding or beading and nail it into the skirting board as opposed to nailing it in the planks since doing so will restrict them from expanding or contracting.

2. Adding Caulk

Caulk can be an especially versatile solution in this regard. It is not only capable of accommodating the expansion and contraction of your boards but can also be used to enhance the water resistance of laminate surfaces in rooms exposed to a high degree of moisture.

It will also be possible for you to obtain products that match your preferred color, with this option.

3. Make Use of Flooring Spacers

These accessories are extremely useful for ensuring you get your expansion gap right the first time and come in different varieties.

Some of the most popular examples include:

a) T Floor Spacers

Robust enough to withstand minor accidents, these spacers will remain in place, unlike tabs that may slip during the installation process.

As a result, these accessories which are capable of measurements of ¼ and ⅜ inches (depending on which sides you use) will enable you to lay your laminate boards in a straight line.

And they’re affordable too, making them well worth their value for money.

If the room you happen to be working on is larger than 500 square feet in size, you may need to consider buying more than a single pack.

b) Tezoro Floor Spacers (24 pack)

These scientifically designed triangular floor spacers are just what you need to achieve that perfect quarter-inch expansion gap.

And they’re pretty stable too. That means you’ll be able to focus on installing those boards without having to keep a sharp lookout for spacers that simply won’t stay put.

All of which makes these accessories ideal whether you happen to be a professional or DIY enthusiast installing a laminate surface.

c) Bessy Floor Spacers

Made from glass-filled nylon, these spacers are adjustable in terms of measurements and tightness.

Their size also means they won’t slip out of sight while you work with them.

What’s more, their special design means you will be able to lay impressively straight rows even when working with slightly irregular walls.

And once you’re through, you will simply be able to loosen them with a twist.

These features ensure the Bessy Floor Spacers are able to provide the ideal blend of convenience and accuracy.

Conclusion

Expansion gaps are necessary when installing laminate surfaces since they provide the space the planks will need to expand as ambient moisture levels change.

If they are omitted issues such as peaking or buckling may result.

According to experts, the minimum recommended size for expansion gaps is a quarter of an inch. However, the size of the gap will depend on the size of the surface being installed.

It is worth noting that this gap will also be required at intervals for areas larger than 12 meters in length and 8 meters in width. Expansion gaps are also necessary when transitioning from one surface to another and may be concealed by transition profiles.

To prevent your expansion gaps from becoming too large or visible as humidity levels fall, you will need to make use of spacers and also acclimatize your laminate flooring. You may also need to use humidifiers during colder seasons.

In the event of your expansion gaps being too large or becoming noticeable, you will have the option of concealing them with molding, beading, or caulk.