The laminate flooring in warm golden brown tones not only looked just like real wood but also came at a price that was a fraction of the real deal. What’s more, your favorite cousins promised you it would be easy to install.

And when they were all done it made your dining room look as though it was worthy of a feature in Architectural Digest. Until you started noticing the presence of tell-tale spaces close to the walls, when winter set in.

Were the expansion gaps left when installing your floor actually too big? Or could the issue have been caused by other factors? What could the reason be for their becoming especially noticeable?

Laminate floor planks are mostly made up of wood (about 90%). Owing to the porosity of this material they tend to shrink and expand due to changes in humidity and temperature, just like solid or engineered hardwood planks.

As a result, they can expand when the weather gets warmer and contract when it gets colder, making any gaps or spacing especially visible.

Noticeable expansion gaps can be fixed by the following methods:

- Removing and replacing your planks

- Adding molding

- Adding beading

- Caulking

Below you will be able to find detailed information on each of these options. You will also be able to find additional helpful pointers such as the perfect size for expansion gaps and how to ensure you get it right the first time.

How Big Should Expansion Gaps For Laminate Floors Be?

Expansion gaps are essential when installing your laminate floors to ensure your planks have enough space for movement when they start to expand during those sunny summer months.

Failure to account for this may result in their pushing against each other as temperature and humidity levels rise, an incidence which may result in buckling laminate floors. (Conversely, falling temperatures, and humidity levels may result in your laminate floor planks separating.)

In addition to detracting from the aesthetics of your surroundings, buckling can also damage the interlocking mechanism of your laminate planks, resulting in extra expenditure to have them replaced.

The minimum recommended size for an expansion gap is a quarter( ¼ ) of an inch. This precaution must be taken around any structures such as cabinets, stairs, and pillars.

How to Fix an Expansion Gap That Has Gotten Too Big

If your laminate flooring expansion gap has gotten too large, you will be able to rectify the issue using a number of straightforward methods explained in detail below.

1. Replace the Entire Floor

Depending on the size of the floor and the state of the room and whether you have furnished it, this may prove to be rather labor intensive.

What you will need to do is remove the molding and then starting with the first row closest to the wall remove each plank. You will need a chisel to lift up each board.

Special care should be taken when removing the planks to avoid damaging the click mechanism.

You will then need to reinstall your floorboards taking special care to leave the required expansion gap recommended by the manufacturer of the laminate floor.

2. Make Use of Molding

Molding can prove especially helpful in concealing wide expansion gaps in your laminate floor.

Ensure you select the correct size which will cover the spaces between the walls and your floor; the material should be solid wood.

It is also a good idea to select molding in a color that is as close as possible to your laminate flooring. However, it may also be possible to stain it.

Once you have obtained a suitable product, you will need to nail the molding into the baseboard.

The molding must never be nailed into the laminate itself since the floor needs to be left free to contract and expand.

3. Make Use of Beading

When using this option you will need to measure the length required as well as the width of the visible part of the expansion gap to ensure you make the right selection.

(As is the case with molding, you will also need to ensure that the color of the beading is pretty close to your laminate flooring. You should also make sure it is waterproof if you intend to use it in a kitchen, bathroom, or mudroom.)

You may also need to cut a 45° angle at the end if the length you will be fitting will also be meeting another at a corner in the room. You will need to use a miter saw to achieve a perfect cut.

An adhesive such as super glue will be suitable for sticking the angled ends together before fitting them into a corner. (Holding them together for a quarter of a minute will ensure the glue will bond both pieces together effectively.)

As is the case with molding, the beading should be attached to the skirtboard and not the laminate flooring to allow for contraction and expansion or even movement as a result of traffic.

If using glue, opt for a strong variety and wipe the excess off with a cloth once you are through. (You may also need to push heavy objects up against the beading until the glue dries.)

Alternatively, you may also use nails to fasten the beading to the skirtboard.

4. Make Use of Caulking

This method can be especially beneficial owing to the ability of caulk to accommodate the movement of your floor. It is also possible to obtain a product which matches your preferred color.

The first thing you will need to do before getting started is to use a vacuum cleaner to thoroughly clean the expansion gaps you intend to cover.

When applying the caulk, you will need to apply consistent pressure on the trigger of the caulk gun while drawing it backwards.

Next, you will need to pull your finger along the line of applied caulk to press it down lightly. It will take about an entire day to dry.

Caulking can also be used to seal the space between tubs and shower stalls and reduce the susceptibility of your flooring to damage by water that may seep beneath the planks.

Building experts specifically recommend the use of silicone caulk for this purpose.

How to Prevent Big Expansion Gaps

Remembering to provide expansion gaps when installing your laminate flooring is important. However, it is just as essential to ensure they are the right size while also taking into account the sensitivity of laminate flooring to changes in temperature and humidity.

Taking the following precautions will enable you to do so:

1. Make Use of Floor Spacers

Floor spacers come in different measurements and varieties. There are those which come in the form of rectangular tabs which you simply slip in between the laminate boards and the wall when installing your flooring. There are also those which are shaped like triangular tabs and tend to have greater stability.

You are also likely to come across floor spacers that lie flat on the floor and can be adjusted and tightened. They are reputed to be especially useful in terms of being able to assist you to lay your laminate flooring in a straight row. Their stability is also another plus.

Alternatively, it is also possible to make floor spacers yourself from yardsticks, for example.

Regardless of which option you choose, you should ensure the expansion gap is the right size recommended by the manufacturer to prevent problems with your flooring. If you are not certain, you may verify it with them since this value is often determined by the size of your floor.

2. Acclimatise Your Flooring

Like solid and engineered hardwood floors, laminate floors need to be acclimatised. This process will ensure your laminate floor planks become accustomed to humidity and temperature levels in the room in which it is meant to be installed.

Failure to take this step will lead to the boards expanding or contracting once they have been installed and may even result in your warranty being voided by your manufacturer.

3. Make Use of Humidifiers in Cold Weather

Laminate planks are especially prone to shrinking in winter and autumn due to falling temperatures and humidity levels. Making use of a humidifier during those colder months could add some much-needed moisture to your surroundings, and possibly prevent shrinking in your laminate floorboards.

Conclusion

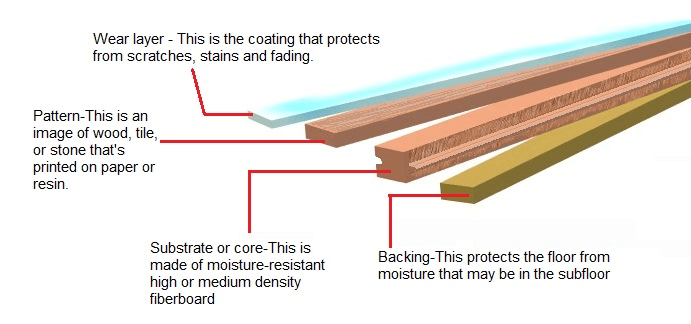

Laminate floor planks mostly consist of high-density fiberboard, and as a result, are rather porous. This quality means that they will either shrink or expand depending on the weather or season.

This may affect your expansion gap and make it appear visible. However, by shifting the boards together, using molding or beading, or simply relying on caulk, you will be able to conceal them.

This condition can also be prevented by ensuring you obtain the recommended expansion gap size for your floor from the manufacturer, acclimatize your laminate boards, and use a humidifier during colder weather.