How to Install Glue-Down Hardwood Flooring

A glue-down hardwood floor is one of the strongest and most durable floor materials you can choose. These floors are made of engineered wood, which is thin layers glued together for maximum strength and stability.

Gluing down a hardwood floor is a lot of work and requires some special knowledge. This guide is here to tell you everything you need to know to DIY a glue-down wood floor.

To protect your investment in high-quality flooring, it’s key that you follow the steps below and plan ahead at every step. If you do that and install your glue-down floor correctly, it should last you for many years.

How Much Hardwood Flooring Do I Need?

Hardwood flooring is sold by the carton, so you will need to know how many cartons to buy.

Start by getting a good measurement of the room. If you are buying your flooring in person, the salesman may be able to come to your house and measure the rooms for you.

After you have an accurate measurement of the whole area where you plan to install hardwood, you need to add some extra flooring to account for the cutting process and damaged pieces that you won’t be using.

Flooring experts recommend you add 5% to the total area for cutting waste. You should also add about 10% for defective or damaged boards in the package.

That means that if you are installing hardwood in a room of 200 square feet, you should order about 230 square feet of flooring (115% of the room’s area).

This much extra wood will ensure you can finish the floor without ordering more flooring and you will probably have a few boards left over in case you need them for a repair in the future.

Quarter-Round and Transition Pieces

Quarter-round is a special trim designed to make the edges of your hardwood floor look smooth and neat as they meet the walls. There are also various wooden transitions you can use to blend your hardwood into rooms with other flooring types.

Measure all the edges of your rooms and choose the right transitions. You may want to order an extra 10%-15% of material, when practical, to allow for cuts and defects.

Order all quarter-round and transition pieces in a matching stain color.

Preparing the Subfloor

The surface below a hardwood floor is very important. It needs to be smooth, clean, and flat to ensure a good hardwood installation. The good news is that engineered hardwood flooring can be glued down on top of a concrete floor and even in a basement, both factors that were impossible with traditional solid wood flooring.

To prepare your subfloor for wood flooring, take a long straightedge or level and use it to check for high and low spots on the floor. If the straight edge rocks from end to end, there is a high spot in the middle. If the ends of the straightedge touch the subfloor but the middle is unsupported, there is a low spot.

Any variation greater than ¼ inch over a 6-foot span needs to be corrected. Smaller variations are ok. If the floor is severely off of level, you may need to lay ¼-inch plywood underlayment across the whole floor. If you just have a few spots to correct, you can use the following steps.

How to Level a Concrete Subfloor

You can fill low spots in concrete with an affordable concrete patch mix. Just spread some of the patch out on the low spots with a wide putty knife and blend it evenly to the edges.

There are some products that you pour onto a floor as a liquid and they then set up as a solid, self-leveling patch. These are expensive and harder to use, so try to stick to a regular patch mix unless you have special circumstances.

You can use a stiff metal scraper or a heavy chisel and a hammer to knock off small high spots on the concrete.

How to Level a Wooden Subfloor

On wood subfloors, it’s easy to lower high spots with an electric sander. Use medium-grit sandpaper to remove a layer of the flooring until it falls within the ¼-inch over 6 feet range. It doesn’t need to be perfectly flat, just within that allowance.

To raise low spots, you can use the same type of concrete patch material listed above. It’s one of the only ways to spread an even layer of the shape you need. Use a wide putty knife to make the subfloor flat using patch mix. Do not use a self-leveling liquid patch on a wood subfloor because it can pour through any seams in the wood.

Preparing the Baseboards and Doors

When you install a hardwood floor, you will be adding thickness to the subfloor. Most hardwood planks are ¾-inch thick. Raising the floor by this much will require moving all of the trims and door jambs up so that the new wood floor can fit under them. Remove the trim pieces and replace them after the floor is completely installed.

Go around the room and pry all the baseboard trim off of the walls. You might want to write a word or two on the back of the trim so you can remember where it goes, especially if you have many pieces of baseboard. Remove the nails from the baseboards and the walls. You will use new nails to replace the trim later.

Cut under door jambs using a hand saw or an oscillating saw. Measure up from the subfloor and mark ¾-inch or whatever the thickness of your new hardwood so you can slide a piece of the flooring under the entire door jamb. Flooring installers have special saws to cut under jambs quickly, but you don’t need one for your DIY project.

Before you cut the door jambs, you should remove the doors from their hinges. You might also need to cut some length off of the bottom of the door so it doesn’t drag on the new, higher floor.

Acclimating Hardwood Flooring

You can think of hardwood flooring as somewhat of a living material. It expands and contracts slightly when the temperature and humidity around it change.

This process of expansion and contraction can ruin a new floor if you do not allow enough time for the material to acclimate to the room before gluing it down.

You can check out our article on acclimating new hardwood flooring to ensure your material is ready to be installed.

The basics of accumulating new hardwood include:

- Let the wood sit in the room where it will be installed for at least 72 hours (maybe longer)

- Open up the packages so they can be exposed to air

- Don’t acclimate wood to a room until windows and doors are installed and the paint is dry

- Run heating and air systems like normal and keep the room temperature at a stable living temperature throughout the process

Choosing Which Direction to Lay the Hardwood Floor

To choose which way to lay your hardwood floor, you should think of both strength and visual appeal.

The most solid direction for your flooring is probably perpendicular to the floor joists beneath the subfloor. You may also consider the seams in the subflooring. You should lay the wood perpendicular to the longer seams so that you gradually bridge any unevenness. These two factors will help make a strong, flat floor for years to come.

Visually, hardwood flooring looks best if it aligns with the straightest walls in the room. These are usually the exterior walls. You may want to align the flooring parallel to an exterior wall in the room.

If your subflooring is very strong and flat, you can choose to run your hardwood for visual appeal rather than across the floor joists or seams.

How to Install A Glue-Down Hardwood Floor

When installing any flooring product, make sure to read the installation instructions that the manufacturer provides. They will tell you the specifications for your exact hardwood product. Follow them closely to make sure you qualify for any warranty offers.

Make sure you understand and complete the above guidelines for preparing your room, acclimating the flooring, and choosing a direction to lay your hardwood floor.

Throughout all the steps, keep in mind that installing hardwood floors requires patience and planning ahead. Before laying a piece of wood floor, visualize how it will look in the room and next to the surrounding planks.

Also, remember when measuring that you will be using spacers to keep all flooring ½-inch away from all walls. You will also need to leave gaps of certain sizes for any transition pieces where your wood flooring meets another material.

Gather the following tools and materials before you begin and see the complete steps for gluing down your new hardwood floor:

Tools and Materials

- Electric chop saw or miter saw

- Electric table saw

- Nail gun

- Chalk line

- Tape measure

- ½-inch plastic spacers

- 100-pound flooring roller

- Flooring adhesive trowel (use the recommended tooth size for your flooring and adhesive)

- Flooring adhesive (use the recommended type for your flooring product)

- Clean, white rags

- Mineral spirits or a urethane adhesive remover

Step 1: Measure the First and Last Rows

To improve the appearance of your finished floor, you should make sure that the first and last rows you install are the same width. After you determine the direction you are going to lay your hardwood floor, find out how many rows will fit in the room.

For example, if you are installing a hardwood product with 6-inch-wide planks, and the room is 10 feet and 2 inches, you have room for 20 whole rows and a 2-inch row.

Instead of having a tiny, 2-inch row at one side of the room, the floor will look better if you cut 2 inches off of the first row and the last row. This will leave you with shorter rows at each end so the two ends of the room look the same.

It’s also important to do this because no row should be smaller than 2 inches wide. If you don’t plan ahead, you may end up with a 1-inch row at the end of the room. Not only will this look bad, but it will also be too small to stick to the glue properly.

It is always better to split the remainder before you start laying the floor and cut the first and last rows in the room to the same width.

Note: Remember that you need to leave an expansion gap of ½ inch between the flooring and all walls, cabinets, and other obstacles. Subtract this gap from your measured end rows.

Step 2: Set Out Cartons of Wood Flooring

Arrange open cartons of planks around the room in short stacks. This will make them easy to reach as you lay the floor. It’s also very important that you pick pieces of wood from multiple cartons.

Wood flooring can vary in color between cartons. Some boxes may be all light wood, and some may be all dark wood. To ensure an even look in your finished room, put planks from a variety of cartons in each row as you install.

Step 3: Do Not Use Any Damaged or Defective Wood Pieces

As the flooring installer, you have a responsibility not to use any planks that you find are defective. As you take a piece of hardwood from the carton, inspect the tongue and groove to make sure they are cut properly and check all corners for chips. Any weird textures or problems with the finish can also be a bad sign.

Since wood is a natural product, it is normal for some pieces to be substandard. But if you find a large number of defective pieces, contact the manufacturer or salesman for a refund of the damaged materials.

If you fail to do this, you forfeit any right to replacement because installing the wood is considered accepting the quality. Do not glue down any piece that you find has problems.

Installing defective wood can also cause buckling or otherwise ruin your new floor. You might also void your warranty by using these pieces. Play it safe and set aside defective material.

Step 4: Set a Chalk Line For The First Row

The easiest way to begin laying your hardwood floor is to start two rows from the wall, lay rows all the way to the far wall, and come back at the end to lay in the first two rows.

To do this, you need to measure from the wall at each end of the room. Use a tape measure to mark the width of the first row (this should be the partial row that you already measured in step 1) plus another whole row.

Once you have a point on each end of the room for the width of the first two rows, snap a chalk line on the subfloor to connect the points.

You will use this chalk line to start laying flooring all the way to the far side of the room. When you are done, you can come back and lay the two rows that you measured in.

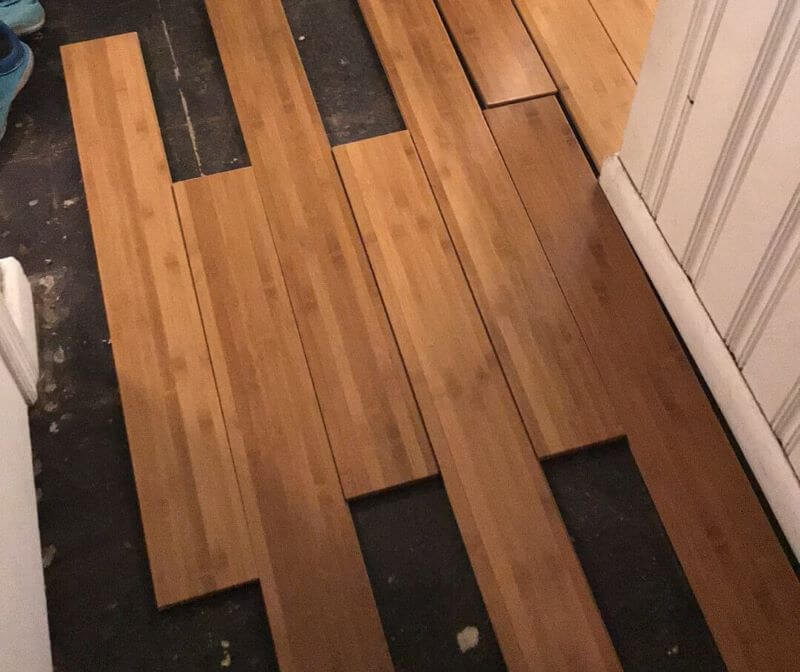

Step 5: Lay Out The First Three Rows

This step is about creating a strong and visually appealing base to begin your hardwood installation.

Pick pieces and lay them out next to each other along the chalk line. Do not worry about using any glue or connecting the tongues just yet.

Pay attention to the seams between boards. The seams in adjacent rows should never line up within 6 inches of each other. Overlapping the boards looks better and makes for a stronger floor.

Avoid creating a patterned appearance. A random scattering of seams will always look better than a pattern.

Remember, you cannot change the alignment of boards after you glue them down. Make sure to stand up and look at the arrangement for each row from a distance. If you notice any rows where seams line up too closely, choose a different board or alter the starting place for the row.

Once you have selected boards that look good together, click the tongues together and make sure they fit nicely along the chalk line.

You will probably need to cut some end pieces to complete the rows. Measure and mark the length you need. Remember to always measure the finished surface of the board, excluding the tongue.

Always use spacers to leave a ½ inch expansion gap between the flooring and all walls, cabinets, and other obstacles. Subtract this length from any cuts you measure.

Step 6: Glue Down The First Three Rows

Once you have laid out your first three complete rows, you are ready to start gluing.

Gently separate the wood pieces you laid out for your first three rows. Lay them nearby so you can replace them after you spread the adhesive.

Use the recommended trowel to spread an even layer of hardwood floor adhesive on the subfloor, starting from the chalk line. Hold the trowel at a 45-degree angle to the floor. Apply firm pressure and use sweeping motions to make an even coat.

Do not spread adhesive on the whole floor. Just completely cover the area you need to glue the first three rows that you already laid out.

After you spread the glue, begin laying boards. Start from the side with a groove end and work toward the tongues. Lay the piece along the chalk line first, then work your way to the other end of the row.

You can work on two rows at a time. This will help create a more stable base as you lay the flooring.

Take the time to tilt each groove around the previous tongue and create a tight fit on every seam. You may need a tapping block to bump the tongues completely into their grooves (preferably a dense plastic block, but a piece of 2×4 and a hammer will do).

Some excess glue will usually squeeze up between the boards. Clean this up immediately with a clean rag and water. You may also use mineral spirits or a urethane adhesive remover on the rag if the adhesive package recommends it.

Step 7: Continue Laying Rows

As you move past the three starter rows, follow a similar pattern. You may wish to lay out whole rows at a time as you did before so you can be sure not to overlap seams within 6 inches of the previous row.

Remember to stagger the starting board length by cutting your first piece of flooring on each end of the row. You can often use the cutoff from your starter plank as an end piece on a later row. Try to do this whenever possible to avoid wasting material.

Spread only enough glue at one time as you can complete it within about 30 minutes. This is probably only 2-3 rows of glue, depending on how long your rows are.

Remember to always plan ahead, avoid a patterned appearance, and never install a defective plank. Also, remember to leave a ½-inch expansion gap between the flooring and the walls.

Step 8: Lay The First and Last Rows

When the majority of the room is finished, you are ready to cut in the last row and first row that you measured for in the beginning.

Use a table saw to rip boards down for width. Leave a ½ inch expansion gap around all obstacles. Slide the boards under any door jambs (which need to be undercut to the thickness of the flooring, if you didn’t do that earlier).

Step 9: Use a Flooring Roller

This step will probably require renting a specialized flooring roller, but it is critical to ensure your flooring bonds to the glue permanently.

Obtain a long-handled roller weighing at least 100 pounds. Local tool-rental companies or flooring installers can help you find one.

Place the roller at one end of the room and slowly roll it back and forth a few feet at a time. Stand to the side of the roller’s path so you don’t hit your feet.

Roll over the whole floor in all four directions.

This will ensure that every board is pressed firmly into the adhesive and create a strong bond.

Step 10: Install Quarter-Round and Transition Pieces

Once you lay all of the flooring, you will need to hide the ½-inch expansion gap around the room. This is what quarter-round and transition pieces are for.

If you have baseboard trim to replace, use a nailer to attach those first. Then you can use the nail gun to attach quarter-round to the walls.

Measure and cut each piece for length. Miter-cut corners at a 45-degree angle. Lay the pieces in to make sure they fit neatly, then nail them to the walls (never to the flooring).

Follow a similar process to measure, cut, and nail any transitions where your wood floor meets the carpet, tile, or other flooring types, or on stair noses. These transition pieces should be nailed to the subfloor.

Table of Contents